Color Industry

The demand for colored goods has always created opportunities for fortunes to be made in the mining and crop cultivation which supplied raw materials, and in the dyeing trades to produced colored textiles and leathers. The Medici fortune was built on their exclusive commission to mine the alum (the primary mordant used in dyeing) which had been discovered in Papal lands in the 15th century and desperately needed since the Turks had captured Constantinople at cut off the previously prevalent supply. The dyeing industry itself was governed by guilds and techniques remained relatively unchanged until the 19th century when mechanized processes were developed.

The late 18th and early 19th centuries also saw the development of a pigment manufacturing industry as chemists discovered ways of creating new colors and established businesses to produce these pigments. Manufacturing also took over the business of paint and ink production with machinery to grind and process the pigments and soon off-the-shelf products were available for artists and printers alike who previously had created them as needed from scratch using materials bought at the apothecary shop. The first ready-made paints were watercolors packaged as hard cakes of pre-mixed colors, but it was the development of the sealable paint tube in 1841, by American painter John Rand, that revolutionized the pre-packaged color industry for artists.

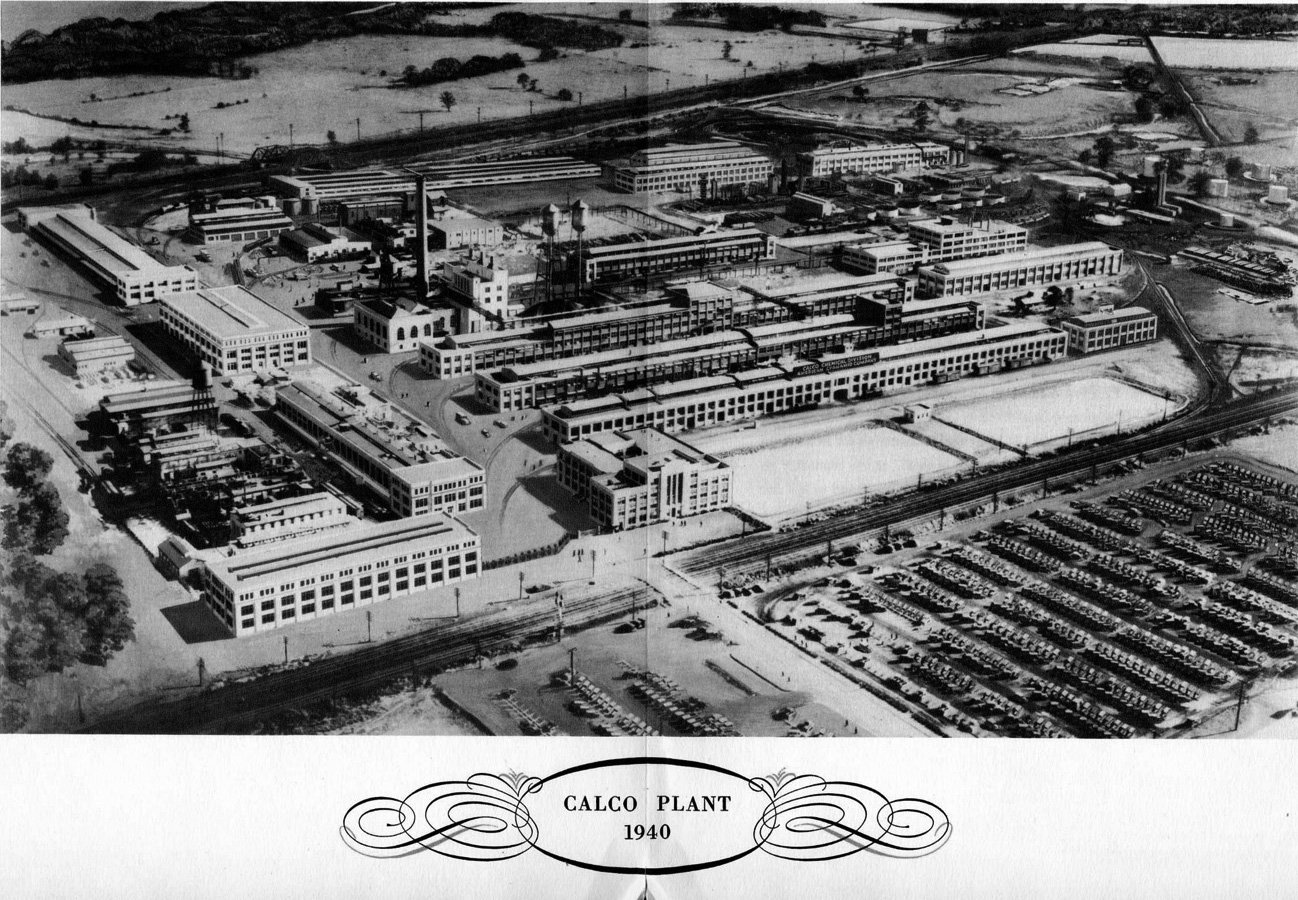

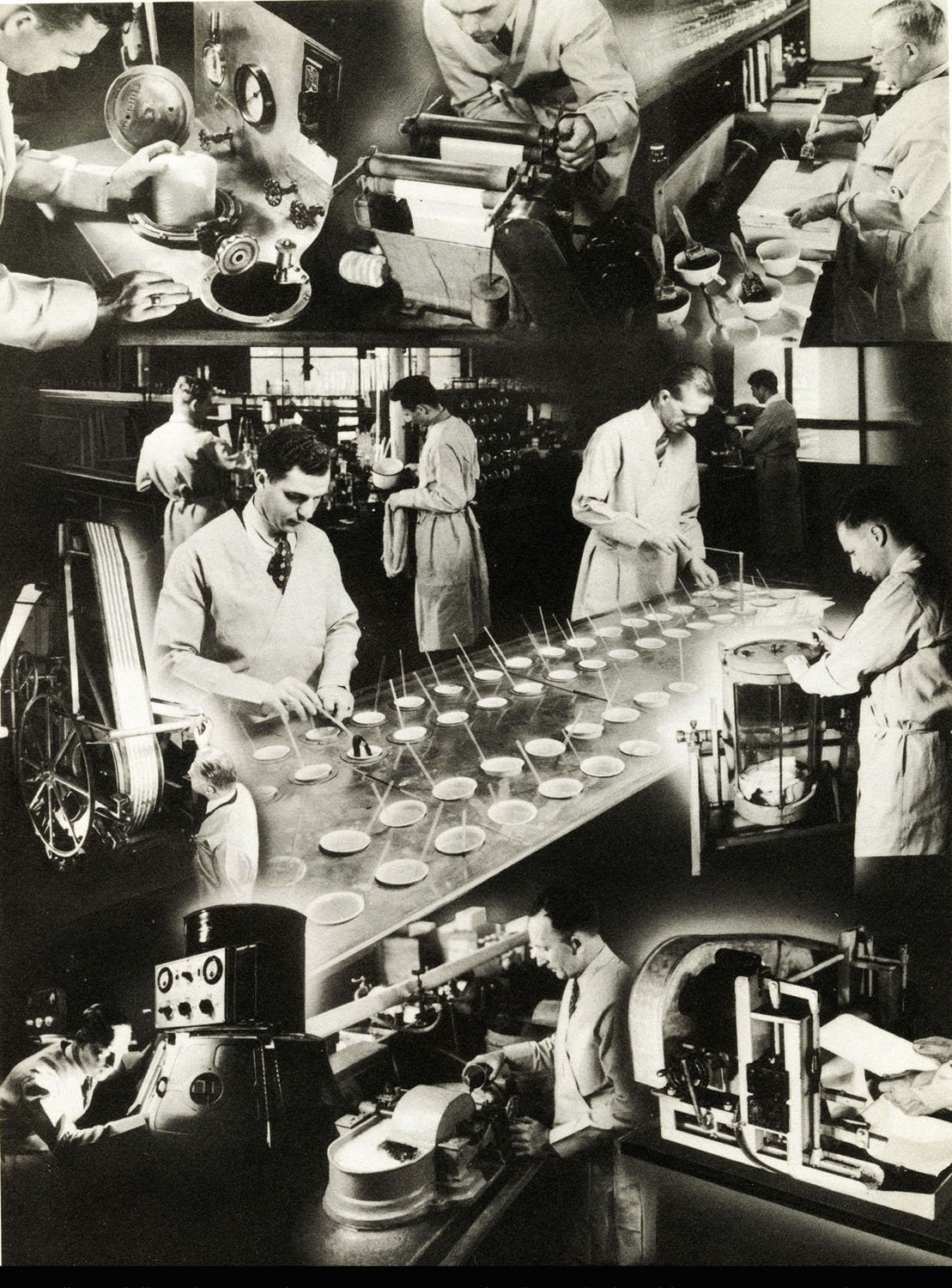

With the rise in synthetic colors, the color industry increasingly equated with chemical manufacture. Despite the radical changes in production, color continued to be tied to medicinal production. Just as the minerals and plants traditionally used for color were also valued for their therapeutic and toxic qualities, the chemistry test labs which produced the new colors also developed medicines and pesticides—the Bayer dyestuff factory, of Aspirin fame, being just one example. Factories became large complexes with research labs, application labs, and the quality control functions in addition to the processing plants for the necessary intermediary ingredients and manufacturing plants for paint or dye production. In the 20th century, plastics were added to the list of materials being developed in these chemical plants. And never far from the fortunes of war and its concomitant effect on supply and demand, the color industry waxed and waned with the outbreak of both World Wars.